Post World War II Facade Technology Overview: Innovations & Lifecycle Challenges

David Fixler, FAIA/FAPT, Principal, David Fixler Architecture Planning Preservation & APT Technical Committee on Modern Heritage Co-Founder

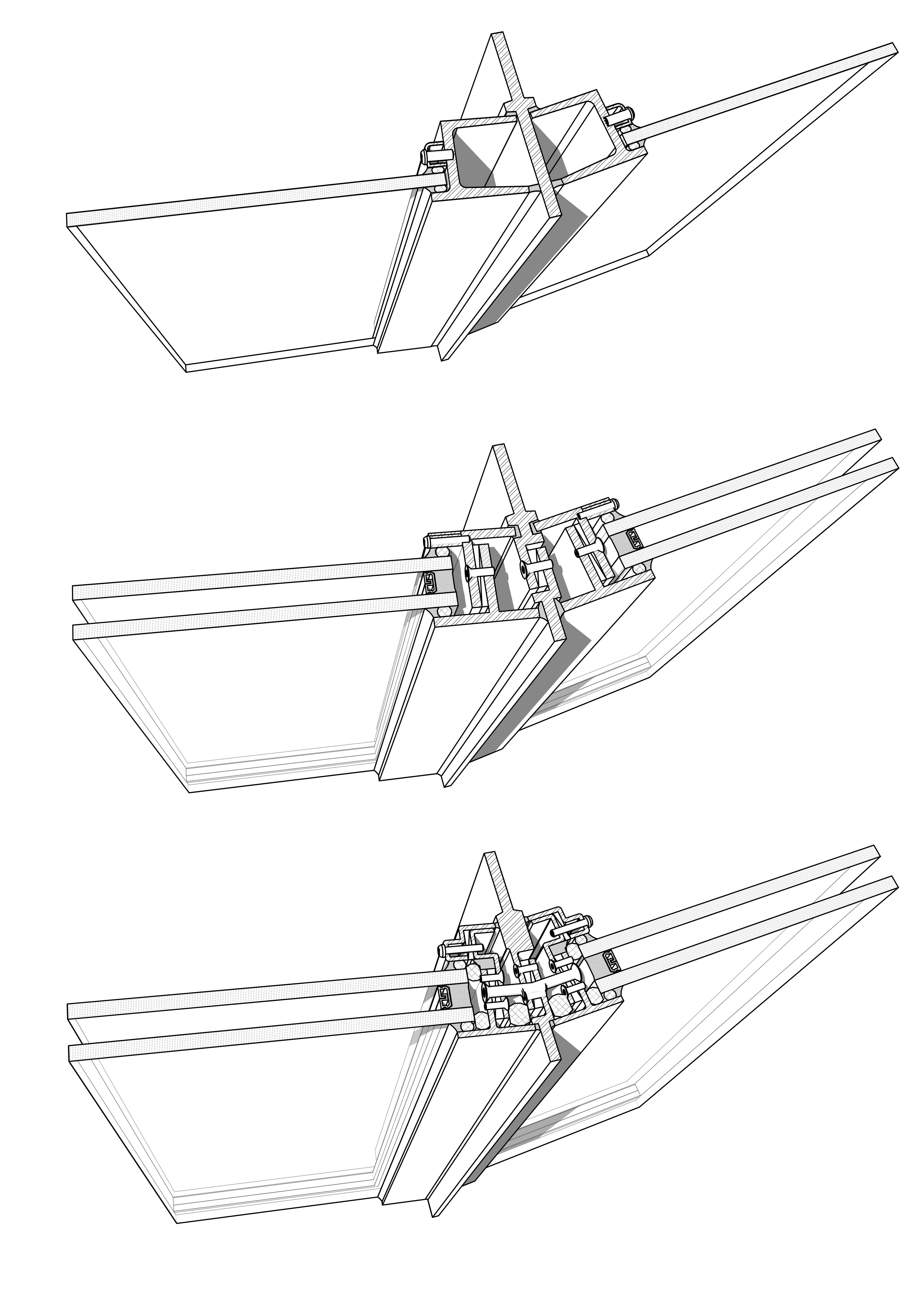

An important and highly consequential innovation in design and construction technology in the post-World War II era was the development of thin exterior envelopes and in particular, curtain wall construction. Though employing a wide range of materials, the predominant systems were metal and glass assemblies clipped to concrete or steel structural frames. The integrity of these systems depended to a large degree on an array of synthetic seals, gaskets and fasteners to hold the assemblies together and ensure sound attachment to the structure. Over time, most of these components have reached the end of their service lives and must be renewed or in most cases replaced. During this period, starting after the mid-1950s, there was also a trend toward more expressive architectural language in search of relief from the ubiquitous and generally anonymous language of the typical curtain wall system. The initial manifestation of this trend came in the “New Formalism” of architects as diverse as Edward Durell Stone, and Eero Saarinen. By 1960 the influence of Le Corbusier’s Beton Brut and a desire for a more “honest” expression of structure led to the development of what has become known as Brutalism, where concrete becomes both the structure and the architecture itself. This mode of expression was largely abandoned following the energy shocks of the 1970s, reverting to new forms of thin wall systems, like rain screens, albeit with more insulation and better energy performance than their predecessors. However, there is a substantial legacy of exposed concrete construction in North America and around the world, and in most climates weathering and deterioration from a number of causes has spawned a robust repair culture within the conservation community and the building industry.

This presentation will be an overview of the development of the envelope typologies that came to largely define architecture from 1945-2000, and that continue to this day, and will introduce the challenges to the designers, conservators and building owners charged with undertaking renewal campaigns to extend the life of these structures, while seeking solutions with minimal environmental impact.

Identifying, Removing, Mitigating Hazardous Materials

Bill Parks, Senior Project Manager, F.D. Thomas

With hazardous substances commonly used in US building and decorative materials until the late 1970s and 80s, conserving heritage sites and trying to retain as much original fabric as possible can be challenging. Thorough research, materials testing, documentation, and development of work and safety plans prior to implementing treatments are vital to retaining historic material and ensuring ongoing public safety. This talk will discuss various approaches to identifying possible hazardous materials at historic sites as well as approaches to their removal and mitigation, to a treat or encapsulate them in situ.

This presentation discusses approaches to the removal of lead paint and concrete repairs in a historic salmon hatchery in Sitka, Alaska. To minimize disruption, the project was undertaken while the building was still in operations for office staff and marine life. This included containment, collection, negative air, monitoring, and OSHA compliance as well as maintaining the historic elements of the building to stay under strict guidelines of the regulatory agency providing funding of the project.

Viewing the Challenge Through the Lens of the Secretary of the Interior’s Standards for Rehabilitation

John Sandor, Senior Historian, National Park Service, Technical Preservation Services

The Secretary’s Standards evolved by 1992 into the form we now know and use, well beyond the projects funded through the federal Historic Preservation Fund. Their broad principles are subject to varied interpretation by their many users. The NPS as both their author and a user, has provided guidance in various forms over the years targeted to the programs we administer. Perhaps relevant, at least in principle, to the topic of this symposium is #16 of the Preservation Briefs: The Use of Substitute Materials on Historic Building Exteriors, which has just been updated. Guidance that once took an appropriately cautious approach, limiting when and how much substitute material could be used, has in practice over time broadened with the expansion of product choices and the increased economic and environmental demands that challenge many rehabilitation projects. The Brief provides guidance on the additional circumstances where substitute materials may appropriately be considered, discusses the properties of an expanded list of materials, and creates a framework for taking those properties into account in order to improve the likelihood of their successful use.

The Brief is not likely to provide direct answers, though, to the philosophical and even more complex technical issues we face with aging composite materials and assemblies. Before tackling the myriad of technical issues these materials and assemblies pose, it is worth reminding ourselves of what the Secretary’s Standards offer to guide our approach. While some might see them as limiting, their language facilitates considerable flexibility. Application of the Rehabilitation Standards in the federal tax incentives program exemplifies some of that flexibility.

Repair, Replacement, and Encapsulation of Asbestos Cement Exterior Panels at the Eames House

Chandler McCoy, Senior Project Specialist, Getty Institute and César Bargues Ballester, Associate Project Specialist, Getty Institute

Completed in 1949, the Eames House, also known as Case Study House No. 8, is one of the most intact and internationally recognized and published works designed under Arts and Architecture magazine’s Case Study House Program. It served as the residence and studio of its renowned designers, Charles and Ray Eames, throughout most of their career, and embodies their reflective, iterative approach to design and their evolving understanding and appreciation of the natural qualities of the site. This presentation focuses on the The Getty Conservation Institute’s study of the Cemesto panels, an essential and culturally significant component of the building enclosure at the Eames residence and studio.

Cemesto is a brand name for an insulating panel manufactured by the now-defunct Celotex Corporation in the United States. It consists of a core of laminated bagasse fiberboard surfaced on both sides with thin asbestos-cement sheets bonded with a bituminous adhesive. Cemesto was marketed as a suitable and durable material with sufficient structural strength, thermal insulation properties, and aesthetic appeal for interior and exterior facing walls, even when left unfinished. Its popularity waned as increased awareness and litigation related to the toxicity of asbestos led many manufacturing companies, including the Celotex Corporation, to file for bankruptcy. The first phase of the study documented historical and technical research, in situ visual condition assessment, and material testing and characterization. The second phase included reviewing applicable guidance, understanding the limitations of preserving hazardous materials, and developing suitable conservation treatments, including repair and replacement, of the Cemesto panels, the sealants, and the steel frame that encloses the panels on the exterior and interior of the residence and studio.

Green Skins for Old Bones: Façade Assembly Design for Adaptive Capacity, Durability, and Disassembly

Mic Patterson, Ambassador of Innovation & Collaboration, Co-founder, Facade Tectonics Institute; Adjunct Professor, USC School

of Architecture

If current goals for energy efficiency and carbon reduction from the building sector are to be realized, much of the existing building stock will require intervention, often including the facade. Retrofit and renovation strategies must respond to the characteristics of widely varying building types. A unique building type prominent in the urban areas of developed countries is that of the tall curtainwall building. Making extensive us of glass infill–often single glazing–these building were never good energy performers or comfort providers. Now many of them are in serious need of renovation, but the failure to anticipate the need for future interventions in the original designs represents a significant barrier to their implementation, owing to significant cost and

disruption to ongoing building operations. In addition, the message of embodied carbon—coupled with recognition of the time-value of carbon—demands that these interventions be as minimal as possible in their embodied carbon impact.

The practices utilized in accomplishing these needed façade upgrades and renovations will ultimately determine whether they will represent a net benefit or just another burden to the economy, society, and environment. It is vital that these rehabilitation projects be carried out in a sustainable manner. Upgrade strategies must be designed for disassembly to facilitate ease of maintenance, repair, and future upgrades. The design of contemporary curtainwall assemblies, whether for new construction or renovations, fail to anticipate these needs, with the implication that we are quite busy building tomorrow’s problems today.

Revisiting Past Projects, Rethinking Reinvestment: Balancing Preservation & Performance

Beth L. Savage, Federal Preservation Officer and Director, Center for Historic Buildings, U.S. General Services Administration

This presentation revisits GSA reinvestment projects involving curtain wall buildings, where glazing details and aging sealant are often weak links in exterior wall assemblies. GSA uses post-occupancy performance data to assess the outcome of interventions on a building’s performance over time to guide future reinvestment. Two markedly contrasting case studies focus on high-rise federal office buildings constructed during the 1960s, a time of Government expansion and economizing advancements in construction technology. In the first case, a 32-story high-rise, completed in 1967, received a double wall over-cladding system to preserve an irreparably compromised glass and steel panel enclosure where failure of interior gutters had caused moisture to collect behind the facade, resulting in corrosion and systematic failure of the curtain wall. In the second case, an 18-story, 1965 high-rise clad in aluminum, glass, and granite, was thoughtfully renewed with envelope upgrades that re-sealed and insulated the spandrel panels, glazing, metal facade components, and roofing.

Given its varied inventory and diverse environments, GSA faces many conditions, along with geographically driven requirements, such as seismic safety standards significantly affecting properties in high-risk locations. Regardless of building type or condition, the search for sound and appropriate solutions begins with thorough, expert analysis. GSA’s approach to investing in both modern and traditional buildings ultimately relies on three core “p’s” of preservation: foundational policy, qualified personnel, and deliberative process, to achieve cost- effective solutions that balance stewardship, performance, and sound reinvestment goals. The presentation concludes with a forward look at an evolving policy imperative for prioritizing carbon-conscious historic building reinvestment.

Future-Proofing, Charters, and Standards: Integrating Principles into Practice

Brian Rich, Principal, Richaven Architecture & Preservation

Future-proofing is a process of anticipating the future and developing methods to minimize the negative effects while taking advantage of the positive effects of shocks and stresses due to future events. The goal of future-proofing is to extend the service life of our built environment by making necessary modifications and adaptations while respecting the historic character of the building. The Principles of Future-proofing have been developed as a broader definition of resilience encompassing the concepts of sustainable design and life cycle analysis as well as climate change and cultural heritage preservation.

This presentation discusses the development of the Principles of Future-Proofing and how to integrate them into practice in the context of US and international preservation guidance documents and regulations, including a framework for adoption of Guidance Documents such as the one being developed in this symposium. Horizontally integrated international guidance documents allow for addition of parallel documents that give further clarification to cultural resource management. By contrast, the vertically integrated system of regulations in the United States make adoption of new guidance more difficult to implement because of the challenges of amending codes, laws, and regulations in thousands of jurisdictions that have hard-coded the Secretary’s Standards for Rehabilitation into their requirements.

Symposium Discussion Proceedings and Next Steps

Kelly Sutherlin McLeod, FAIA, Kelly Sutherlin McLeod Architecture, Inc. (KSMA) and Caroline Alderson, FAPT, APT Technical Committee on Modern Heritage

In a series of interactive sessions following the symposium presentations, attendees articulated and ranked recommendations for addressing challenges raised by aging composite materials and assemblies in three categories: prioritizing preservation, prioritizing sustainability, and prioritizing feasibility, or life cycle cost effectiveness. Some recommendations can be implemented by individual APT professionals, such as actions concerned with design, construction, and client education. Other recommended actions require external advocacy and partnership strategies at the organizational level, leveraging APT’s position as a non-profit professional organization with an international membership and mission. These actions will require outreach to organizations supporting owners, applicable industries, and educational institutions. The committee welcomes attendee feedback on refining and moving the next steps forward.